- Home

- OEM Sand Casting Disadvantages

Disadvantages of OEM Sand Casting: Manufacturer's Perspective

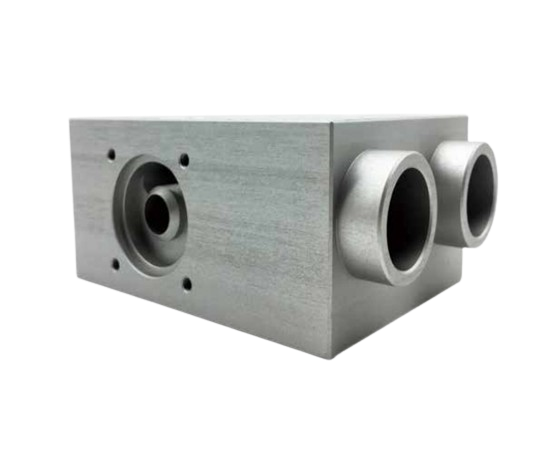

Are you in need of high-quality OEM sand casting products? Look no further than Goodwill Precision Machinery Co., Ltd., a leading manufacturer, supplier, and factory based in China. Our OEM sand casting process allows for the production of complex and intricate parts with excellent surface finishes. However, it's essential to be aware of the potential disadvantages of OEM sand casting. While this process is cost-effective for large production runs, it may not be suitable for small quantities due to high tooling costs. Additionally, there is a risk of porosity and lack of dimensional accuracy with sand casting. Despite these potential drawbacks, Goodwill Precision Machinery Co., Ltd. has extensive experience and expertise in mitigating these disadvantages, ensuring the highest quality and precision in our OEM sand casting products. Trust us to deliver superior parts that meet your exact specifications while overcoming the challenges associated with sand casting. Contact us today to discuss your OEM sand casting needs.

Goodwill Precision Machinery (Dongguan) Co,. Ltd.

Company News

Related News

Vacuum chamber/Semiconductor equipment precision part

PrecisionVac™ Vacuum Chamber: High-quality semiconductor equipment precision parts manufactured at our trusted factory. Order now for superior performance.

Sleeve/Precision instruments part

High-precision Sleeve for Industrial Machinery - Made in our Factory. Find the perfect fit for your precision instruments parts. Order now!

POM custom injection molding plastic part

POM custom injection molding plastic parts - We are a factory specializing in high-quality production of POM injection molded plastic parts.

Base/Precision Instruments Part

Browse our high-quality {Base/Precision Instruments Part} products. As a factory, we ensure superior performance and precision engineering. Shop now!

Body of the endoscope jaw/Biomedical equipment part

Introducing our latest endoscope jaw - perfect for biomedical applications. Explore our factory-direct selection today for top-quality equipment.

PPS Custom injection molding plastic parts

PPS Custom Injection Molding Plastic Parts - Quality plastic parts manufacturing. We are a factory specializing in custom injection molding services.

Molecular cavity/Biomedical equipment precision part

NanoCell Precision Cavity: Leading factory for molecular cavity and biomedical equipment precision parts. High-quality, precise manufacturing." 150 characters.

anesthesia machine free valve box,medical device part

Introducing the "ValveFreeBox" - a key component of our high-quality anesthesia machine. As a factory, we specialize in precision medical device parts.

Automatic X-Ray inspection machine

Get accurate and efficient X-ray inspection with our Automatic X-Ray inspection machine. Perfect for factories. Contact us for your quality control needs.

Dry cell battery baler

Get the best dry cell battery baler from our factory. Our high-quality balers are efficient and durable. Purchase now for an eco-friendly waste solution.

anesthesia machine circuit middle plate,medical device part

Midplate for Anesthesia Machine Circuit - Reliable medical device part manufacturer. Buy direct from our factory for quality assurance.

POM custom injection molding plastic part

POM custom injection molding plastic part - made in our factory with precision and quality. Find the best plastic parts for your needs today.

Semiconductor equipment part

Get the best quality {Semiconductor equipment part} from our factory. We specialize in producing top-of-the-line {Semiconductor equipment part} for all your needs.

PC custom injection molding plastic parts

Get high-quality PC custom injection molding plastic parts at our factory. We provide precision manufacturing for all your product needs.

Winding plate base/Lithium battery precision part

Introducing our Winding Plate Base and Lithium Battery Precision Part. As a factory, we ensure top-quality and precision in every product.

- Disadvantages of OEM Sand Casting: Exploring the Challenges of Manufacturer Casting

- Reviews

- Related Videos

Introducing our new product line of OEM sand castings! We have perfected the art of sand casting to provide high-quality, custom components for a wide range of industries. However, while sand casting is a popular and cost-effective manufacturing process, it does come with some disadvantages. One of the main drawbacks of sand casting is the potential for surface defects and porosity in the final product. This can lead to decreased strength and structural integrity, as well as the need for additional machining or finishing processes to achieve the desired result. Additionally, the tooling and setup for sand casting can be time-consuming and costly, making it less suitable for small production runs or prototyping. Despite these disadvantages, our team has developed innovative techniques and stringent quality control measures to minimize these issues and deliver sand castings that meet our customers' exact specifications. Our expertise in material selection, mold design, and process optimization ensures that our OEM sand castings are of the highest quality and performance. With our commitment to excellence and customer satisfaction, we are confident that our OEM sand castings will exceed your expectations. Contact us today to learn more about how our sand casting capabilities can benefit your next project.

I recently purchased an OEM sand casting product and although it is cost-effective, it comes with a few disadvantages. Firstly, the surface finish can be quite rough and may require additional machining to achieve the desired smoothness. Secondly, the dimensional accuracy may not be as precise as other manufacturing processes, leading to potential rework. Additionally, the lead time for sand casting can be longer compared to other manufacturing methods, leading to delays in product availability. These disadvantages are important to consider when choosing OEM sand casting for your product manufacturing needs.

I recently purchased an OEM sand-cast product and have to say I was disappointed with the quality. The sand casting process seemed to result in rough and uneven surfaces, which made the product look less polished and professional. Additionally, there were some noticeable imperfections and inconsistencies in the finish, which was a letdown. While I appreciate the cost-effectiveness of sand casting, I would have preferred a smoother and more refined final product. Overall, I think OEM sand casting has its disadvantages when it comes to achieving a high-quality finish.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours