Quality Cnc Lathe Turning Suppliers for Your Business Needs

By:Admin

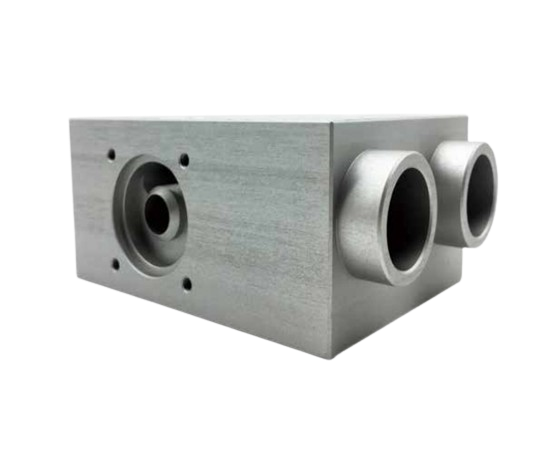

Established in [year], [Company Name] has built a solid reputation for delivering superior machining services to its customers. Specializing in CNC lathe turning, the company has continued to invest in state-of-the-art equipment and technology to meet the ever-changing needs of its clients. With a team of highly skilled machinists and engineers, [Company Name] is dedicated to ensuring that each project is completed with the highest level of precision and accuracy.

As one of the premier CNC lathe turning suppliers in the industry, [Company Name] is known for its ability to handle a diverse range of materials, including aluminum, steel, stainless steel, brass, and plastics. Whether it's creating complex geometries or producing intricate components, the company has the expertise and capabilities to tackle even the most challenging projects. By utilizing advanced CNC lathe turning techniques, [Company Name] is able to achieve tight tolerances and maintain the highest quality standards for every part manufactured.

One of the key differentiators that sets [Company Name] apart from other CNC lathe turning suppliers is its dedication to customer satisfaction. With a focus on building long-term relationships with its clients, the company strives to provide personalized service and support throughout the entire manufacturing process. From initial consultations to final product delivery, [Company Name] works closely with its customers to understand their unique requirements and ensure that their expectations are met or exceeded.

In addition to its commitment to quality and customer service, [Company Name] also takes pride in its ability to offer competitive pricing and quick turnaround times. By streamlining its processes and optimizing its production capabilities, the company is able to deliver cost-effective solutions without compromising on the quality of its work. Whether it's a small batch of parts or a large-scale production run, [Company Name] is dedicated to meeting its customers' timelines and delivering finished products in a timely manner.

Furthermore, [Company Name] understands the importance of staying ahead of the curve when it comes to technological advancements in the field of CNC lathe turning. The company continuously invests in training and development for its team members to ensure that they are equipped with the latest knowledge and skills to tackle the most demanding projects. By staying abreast of industry trends and innovations, [Company Name] remains at the forefront of CNC lathe turning services and is well-positioned to adapt to the evolving needs of its customers.

With a strong commitment to quality, customer satisfaction, and continuous improvement, [Company Name] has solidified its position as a trusted partner for companies seeking reliable CNC lathe turning solutions. By leveraging its expertise, advanced capabilities, and unwavering dedication to excellence, [Company Name] is poised to continue serving as a leading supplier in the industry for years to come.

In conclusion, when it comes to CNC lathe turning suppliers, [Company Name] stands out as a reliable and trusted partner for companies in need of precision machining services. With its focus on delivering top-notch results, personalized service, and advanced capabilities, the company is well-equipped to meet the diverse needs of its customers and contribute to their success in the manufacturing industry.

Company News & Blog

Get Quotes for CNC Mill Conversion Kit

[Company Introduction] is a leading manufacturer of CNC milling machines, specializing in providing high-quality equipment for a wide range of industries. With a dedication to precision engineering and innovative technology, [Company] has built a strong reputation as a trusted supplier of CNC equipment.Recently, the company has announced the launch of their latest product, the CNC Mill Conversion Kit. This new offering is designed to provide an affordable and efficient solution for businesses looking to upgrade their existing milling machines to CNC technology. The kit includes all the necessary components for converting a manual mill to a fully functional CNC machine, providing customers with a cost-effective way to modernize their equipment and improve productivity."We are excited to introduce our CNC Mill Conversion Kit to the market," said [Spokesperson], CEO of [Company]. "With this product, we aim to make CNC technology more accessible to businesses of all sizes. By offering a comprehensive kit that includes everything needed for the conversion process, we are empowering our customers to enhance the capabilities of their milling machines without the need for a complete equipment overhaul."The CNC Mill Conversion Kit is compatible with a variety of milling machines, making it a versatile option for businesses with different models and specifications. It features state-of-the-art components, including precision ball screws, linear guides, and powerful motors, ensuring smooth and accurate operation. The kit also comes with user-friendly software that simplifies the programming and control of the CNC system, making it suitable for both experienced machinists and those new to CNC technology.In addition to the hardware and software components, customers who purchase the CNC Mill Conversion Kit will also receive comprehensive technical support from [Company]'s team of experts. This includes assistance with the installation and setup of the kit, as well as ongoing guidance for optimizing and maintaining the CNC system. With a strong commitment to customer satisfaction, [Company] aims to ensure that businesses can make a seamless transition to CNC technology and maximize the benefits of their investment.The launch of the CNC Mill Conversion Kit reflects [Company]'s dedication to continuous innovation and technological advancement. By providing a cost-effective solution for upgrading milling machines to CNC, the company is enabling businesses to stay competitive in today's fast-paced manufacturing industry. With a focus on quality, reliability, and performance, [Company] is poised to further strengthen its position as a leading provider of CNC equipment and solutions."We believe that the CNC Mill Conversion Kit will be a game-changer for businesses seeking to modernize their milling capabilities," added [Spokesperson]. "At [Company], we are proud to offer a product that not only meets the highest standards of quality and precision but also delivers exceptional value to our customers. We are confident that this new offering will empower businesses to take their machining operations to the next level."As [Company] continues to expand its product offerings and enhance its capabilities, the launch of the CNC Mill Conversion Kit represents a significant milestone in the company's journey. With a strong focus on customer satisfaction, innovation, and excellence, [Company] remains committed to driving the advancement of CNC technology and supporting the evolving needs of the manufacturing industry.

How to Properly Molding Mold: Tips and Techniques

Molding Mold, a leading manufacturer of high-quality molds, has been making significant strides in the industry since its inception. With a focus on innovation, precision, and customer satisfaction, the company has established itself as a trusted partner for businesses in various sectors, including automotive, electronics, and consumer goods.Specializing in the design and production of precision molds, Molding Mold utilizes state-of-the-art technology and advanced manufacturing processes to deliver superior products to its clients. The company’s team of highly skilled engineers and technicians work collaboratively to develop customized mold solutions that meet the specific requirements of each customer.In addition to its commitment to quality, Molding Mold places a strong emphasis on sustainability and environmental responsibility. The company actively seeks to minimize its carbon footprint and optimize its manufacturing processes to reduce waste and energy consumption. By integrating eco-friendly practices into its operations, Molding Mold aims to contribute to a healthier planet and set an example for others in the industry.One of the key differentiators for Molding Mold is its dedication to ongoing research and development. The company continually invests in R&D to explore new materials, design techniques, and manufacturing processes that can enhance the performance and durability of its molds. This proactive approach enables Molding Mold to stay ahead of the curve and provide its customers with cutting-edge solutions that drive their business success.Furthermore, Molding Mold has built a reputation for its exceptional customer service and support. The company works closely with its clients throughout the entire process, from initial concept development to final product delivery, ensuring clear communication and collaboration at every stage. Molding Mold understands the importance of meeting deadlines and budget constraints, and it strives to exceed customer expectations with every project.Recently, Molding Mold introduced a new line of molds that are specifically designed for the rapidly growing electric vehicle (EV) market. With the global shift towards sustainable transportation, the demand for high-performance molds for EV components has increased significantly. Molding Mold has risen to the challenge by leveraging its expertise and resources to develop innovative mold solutions that address the unique requirements of EV manufacturers.The new EV molds from Molding Mold are engineered to deliver exceptional precision and durability, making them ideal for producing critical components such as battery casings, charging connectors, and interior paneling. These molds are designed to withstand the rigorous production demands of the automotive industry while maintaining the highest standards of quality and efficiency.“With the rise of electric vehicles, there is a growing need for advanced molds that can support the production of EV components with utmost accuracy and reliability,” said a spokesperson from Molding Mold. “We are thrilled to introduce our new line of EV molds, which reflect our unwavering commitment to innovation and customer-centric solutions. We believe that these molds will play a crucial role in advancing the EV market and driving sustainable mobility.”As Molding Mold continues to expand its product offerings and explore new opportunities, the company remains dedicated to its founding principles of excellence, integrity, and continuous improvement. With a strong focus on technology, sustainability, and customer satisfaction, Molding Mold is poised to shape the future of mold manufacturing and make a lasting impact on the industries it serves.

Top Metal Insert Molding Techniques You Need to Know

Famous Metal Insert Molding, a leading metal insert molding company in the industry, is making waves with its innovative and high-quality products. With a focus on precision and efficiency, the company has established itself as a reliable partner for businesses across various industries.With state-of-the-art facilities and a team of experienced professionals, Famous Metal Insert Molding has the capability to handle complex metal insert molding projects. The company's commitment to quality and customer satisfaction has earned it a stellar reputation in the industry.Specializing in the production of metal insert molded components, Famous Metal Insert Molding offers a wide range of services including product design, tooling, and manufacturing. The company's expertise in metal insert molding allows for the creation of durable and high-performing products that meet the unique needs of its customers.Famous Metal Insert Molding takes pride in its ability to deliver cost-effective solutions without compromising on quality. By utilizing advanced technologies and lean manufacturing processes, the company is able to optimize production and reduce lead times, ultimately providing its customers with a competitive advantage in the market.Furthermore, Famous Metal Insert Molding is dedicated to sustainability and environmentally-friendly practices. The company is constantly exploring new ways to minimize waste and maximize the use of recyclable materials in its manufacturing processes. This commitment to sustainability not only benefits the environment but also demonstrates the company's dedication to corporate social responsibility.In addition to its high standards for quality and efficiency, Famous Metal Insert Molding places a strong emphasis on customer service. The company's team of knowledgeable professionals works closely with customers throughout the entire manufacturing process, ensuring that their needs are met and expectations exceeded. This personalized approach has solidified Famous Metal Insert Molding's position as a trusted partner for businesses looking to develop metal insert molded components.Famous Metal Insert Molding's commitment to excellence and continuous improvement has earned it recognition and accolades within the industry. The company's relentless pursuit of innovation and dedication to customer satisfaction have set it apart as a leader in the metal insert molding sector.With a focus on delivering high-quality products, exceptional customer service, and sustainable practices, Famous Metal Insert Molding continues to be at the forefront of the industry. As the company continues to grow and expand its capabilities, it remains dedicated to upholding its core values of quality, efficiency, and customer satisfaction.As Famous Metal Insert Molding continues to make its mark in the industry, it is poised to set new standards for metal insert molding and solidify its position as a premier partner for businesses seeking reliable and innovative manufacturing solutions. With a proven track record of success and a commitment to excellence, Famous Metal Insert Molding is well-positioned for continued growth and success in the years to come.

Top CNC Machining Company Specializing in Brass Material

(Company Name), a leading CNC machining brass company, has been making waves in the industry with its top-notch precision machining services and high-quality products. With a strong focus on innovation and customer satisfaction, the company has established itself as a reliable partner for businesses looking for CNC machining solutions.The company specializes in providing precision machining services for a wide range of industries, including automotive, aerospace, medical, and electronics. With state-of-the-art equipment and a team of highly skilled engineers and technicians, (Company Name) is able to produce complex parts and components with tight tolerances and superior surface finishes.One of the key strengths of (Company Name) is its ability to work with a variety of materials, including brass, aluminum, stainless steel, and plastics. This versatility allows the company to meet the diverse needs of its clients and deliver custom machining solutions that meet their exact specifications.In addition to its precision machining services, (Company Name) also offers value-added services such as design assistance, prototyping, and assembly. This comprehensive approach allows the company to be a one-stop shop for its customers, providing them with end-to-end solutions for their machining needs.One of the distinguishing factors of (Company Name) is its commitment to quality. The company adheres to strict quality control measures throughout the entire production process, ensuring that every part and component that leaves its facility meets the highest standards of excellence. This dedication to quality has earned (Company Name) a reputation for reliability and consistency in the industry.Furthermore, (Company Name) is dedicated to staying at the forefront of technological advancements in the CNC machining industry. The company continually invests in new equipment and software, as well as ongoing training for its staff, to ensure that it remains ahead of the curve in terms of capabilities and efficiency.To support its commitment to sustainability, (Company Name) also places a strong emphasis on responsible manufacturing practices. The company actively seeks out ways to reduce waste, conserve energy, and minimize its environmental impact, making it a preferred choice for businesses looking for eco-friendly machining solutions.In order to better serve its growing customer base, (Company Name) recently expanded its production facility and invested in additional machining capabilities. This expansion has allowed the company to take on larger and more complex projects, while maintaining its trademark precision and efficiency.The company's dedication to customer satisfaction has also earned it a loyal and diverse client base, including both large corporations and small businesses. (Company Name) takes pride in its ability to build strong, long-lasting relationships with its customers and is committed to working closely with them to understand their unique needs and provide tailored solutions.Looking ahead, (Company Name) is poised for continued growth and success in the CNC machining industry. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is well-positioned to remain a leader in the field and to meet the evolving needs of its clients.In conclusion, (Company Name) is a powerhouse in the CNC machining industry, known for its precision, quality, and commitment to excellence. With a focus on innovation and customer satisfaction, the company continues to set the standard for high-quality machining services and remains a trusted partner for businesses across a wide range of industries.

Quality Plastic Machining Services for CNC Applications

CNC Plastic Machining is a process that involves the use of Computer Numerical Control (CNC) machines to accurately and efficiently shape plastic materials into precise components. This process requires advanced programming and cutting tools to achieve high levels of precision and repeatability. With the increasing demand for custom plastic parts in various industries, CNC plastic machining has become an essential part of manufacturing.One company at the forefront of CNC plastic machining is {}. With over 20 years of experience in the industry, {} has established itself as a leading provider of CNC plastic machining services. The company’s commitment to quality, precision, and innovation has made it a trusted partner for businesses across a wide range of industries.{}’s state-of-the-art facility is equipped with the latest CNC machines, including multi-axis milling and turning centers, as well as advanced CAD/CAM software for programming and simulation. This cutting-edge technology allows {} to produce complex plastic components with tight tolerances and superior surface finishes. Additionally, the company’s team of skilled machinists and engineers are dedicated to delivering high-quality parts that meet the unique specifications and requirements of each customer.With a focus on continuous improvement and staying ahead of industry trends, {} has invested in ongoing training and development for its team, as well as the latest advancements in CNC plastic machining technology. This proactive approach has enabled the company to remain at the forefront of innovation and provide its customers with the most advanced solutions for their plastic machining needs.One of the key advantages of CNC plastic machining is its ability to produce custom parts with high precision and consistency. This is particularly important for industries such as aerospace, medical, automotive, and electronics, where tight tolerances and strict quality standards are essential. The ability to accurately machine intricate plastic components makes CNC plastic machining a cost-effective solution for producing complex parts in large or small quantities.In addition to precision, CNC plastic machining offers a wide range of material options, including engineering plastics such as PEEK, Delrin, and Ultem, as well as standard plastics like ABS, acrylic, and nylon. This versatility allows {} to serve a diverse customer base with varying material requirements, from prototypes to production runs.Furthermore, CNC plastic machining is a sustainable and environmentally friendly manufacturing process. The ability to efficiently produce custom plastic parts reduces material waste and energy consumption, contributing to a greener and more efficient supply chain.As the demand for custom plastic parts continues to grow, {} is well-positioned to meet the needs of a diverse and evolving market. The company’s dedication to quality, innovation, and customer satisfaction has solidified its reputation as a trusted partner for CNC plastic machining services.With a focus on precision, versatility, and sustainability, {} is committed to remaining at the forefront of CNC plastic machining and providing its customers with the highest quality solutions for their plastic manufacturing needs. With its advanced technology, skilled team, and unwavering dedication to excellence, {} is poised to continue driving innovation and delivering superior results for years to come.

How to Get the Best Molding Engineering Products for Your Needs

Molding Engineering Product, a leading provider of advanced engineering solutions, has recently announced its latest innovative product line aimed at revolutionizing the manufacturing industry. With a legacy of excellence and a reputation for delivering high-quality products and services, Molding Engineering Product is poised to make a significant impact in the global market.Established in [year], Molding Engineering Product has continually stayed ahead of the curve by leveraging cutting-edge technologies and a team of highly skilled engineers and industry experts. The company prides itself on providing customized solutions to meet the unique needs of its clients, and its commitment to innovation and excellence has earned it a strong and loyal customer base.Molding Engineering Product's latest product line is designed to address the growing demand for efficient and cost-effective manufacturing solutions. With a focus on precision engineering and advanced materials, the new product line promises to deliver unparalleled performance and durability. The company has invested heavily in research and development to ensure that its products are at the forefront of technological advancement, and its dedication to quality and customer satisfaction is evident in every aspect of its business.One of the key highlights of Molding Engineering Product's new product line is its versatility and adaptability. The company has designed its products to be easily integrated into existing manufacturing processes, allowing businesses to enhance their operations without significant disruption. This flexibility is particularly valuable in today's fast-paced and dynamic market, where companies are constantly seeking ways to improve efficiency and productivity.In addition to its technical excellence, Molding Engineering Product is also committed to sustainability and environmental responsibility. The company recognizes the importance of reducing its environmental impact and has taken proactive measures to minimize waste and energy consumption in its manufacturing processes. By choosing Molding Engineering Product's solutions, businesses can contribute to a more sustainable future while also reaping the benefits of greater efficiency and cost savings.Molding Engineering Product's dedication to excellence extends beyond its products, encompassing its customer service and support as well. The company's team of experts is on hand to provide guidance and assistance to clients, ensuring that they get the most out of their investment. Whether it's technical advice, training, or troubleshooting, Molding Engineering Product's commitment to customer satisfaction sets it apart as a trusted and reliable partner for businesses around the world.Looking ahead, Molding Engineering Product is excited about the opportunities that its new product line presents. With an increasingly competitive market and growing demand for innovative manufacturing solutions, the company is well-positioned to make a significant impact and strengthen its position as a leader in the industry. By staying true to its core values of excellence, innovation, and customer focus, Molding Engineering Product is poised for continued success and growth in the years to come.As businesses look to the future and seek ways to enhance their operations, Molding Engineering Product's new product line offers a compelling solution. With its combination of advanced technology, superior performance, and commitment to customer satisfaction, the company is well-equipped to meet the evolving needs of the manufacturing industry and remain at the forefront of innovation. For businesses seeking a reliable and innovative partner, Molding Engineering Product is a name to trust.

The Ultimate Guide to Aluminium Anodizing Process

Aluminium Anodizing Process: A Look at the Innovative Technology by [Company Name][Company Name] is a leading provider of innovative solutions in the field of industrial manufacturing. With a strong focus on continuous improvement and cutting-edge technology, the company has recently made significant advancements in the field of aluminium anodizing.The aluminium anodizing process is an electrochemical method that enhances the properties of aluminium, making it more durable, corrosion-resistant, and aesthetically pleasing. This process involves creating a layer of oxide on the surface of the aluminium, which can then be dyed or sealed to achieve the desired finish.[Company Name] has invested heavily in research and development to improve the efficiency and effectiveness of the aluminium anodizing process. Through continuous innovation, the company has developed a state-of-the-art anodizing system that offers several key advantages over traditional methods.One of the main benefits of [Company Name]'s aluminium anodizing process is its ability to produce a more uniform and consistent finish. This is achieved through precise control of the anodizing parameters, ensuring that each part is treated with the same level of precision and accuracy.In addition, the company's anodizing system is designed to be highly flexible, allowing for rapid changeovers and quick adjustments to accommodate different part sizes and configurations. This level of adaptability makes it well-suited for a wide range of applications, from automotive components to architectural elements.Furthermore, [Company Name]'s anodizing process is environmentally friendly, with a focus on minimizing waste and energy consumption. The system is designed to operate with maximum efficiency, reducing the overall environmental impact and promoting sustainability.To complement its advanced anodizing technology, [Company Name] also offers a comprehensive range of pre- and post-treatment services, including cleaning, etching, and sealing. This full-service approach allows customers to streamline their supply chain and simplify their manufacturing processes.The company's commitment to quality and customer satisfaction is evident in its dedication to continuous improvement and ongoing investment in cutting-edge technology. By staying at the forefront of industry trends and leveraging the latest advancements, [Company Name] is able to deliver superior results and unparalleled value to its customers.In conclusion, [Company Name] is proud to offer a state-of-the-art aluminium anodizing process that sets a new standard for efficiency, precision, and environmental responsibility. With a focus on innovation and customer-centric solutions, the company continues to push the boundaries of what is possible in the field of industrial manufacturing.For more information about [Company Name] and its advanced anodizing technology, please visit [company website] or contact [company contact information].Overall, [Company Name]'s commitment to excellence and innovation has solidified its position as a leader in the field of industrial manufacturing. With its advanced anodizing technology and comprehensive range of services, the company is well-equipped to meet the evolving needs of its customers and exceed their expectations for years to come.

Precision Machining Services for Small Parts: An Overview

Custom Small Parts Machining Taking Manufacturing to the Next LevelIn the bustling world of manufacturing, precision and quality are paramount. Whether it's creating intricate components for aerospace engineering or producing small parts for medical devices, every detail matters. That's where custom small parts machining comes into play, and one company is taking this process to the next level.With over 20 years of experience in the industry, {Company Name} has established itself as a leader in custom small parts machining. The company specializes in providing high-quality, precision-machined parts for a wide range of industries, including aerospace, medical, automotive, and more. Their state-of-the-art facility is equipped with the latest technology and a team of skilled engineers and machinists, allowing them to meet the most demanding requirements of their clients.Custom small parts machining is a complex process that requires expertise, attention to detail, and a deep understanding of materials and manufacturing techniques. It involves the use of advanced CNC machines and other cutting-edge equipment to produce small, intricate components with tight tolerances. This level of precision is essential for industries where safety, reliability, and performance are critical.{Company Name} takes pride in its ability to deliver custom small parts machining solutions that exceed client expectations. Their team works closely with customers to understand their specific needs and requirements, offering personalized consultation and engineering support throughout the entire process. From prototype development to full-scale production, they are committed to delivering top-quality parts on time and within budget.One of the key strengths of {Company Name} is their ability to work with a wide range of materials, including aluminum, stainless steel, titanium, and various engineered plastics. This versatility allows them to serve diverse industries and provide solutions for a variety of applications. Whether it's a complex aerospace component or a critical medical device part, they have the expertise and capability to deliver precise, high-quality machined parts.The company's commitment to continuous improvement and innovation is evident in their focus on investing in the latest technology and training for their team. They are always looking for new ways to optimize their processes, increase efficiency, and enhance the quality of their products. This dedication to excellence has earned them a reputation as a trusted partner for custom small parts machining.In addition to their technical expertise, {Company Name} also places a strong emphasis on quality assurance and reliability. Their facility is equipped with advanced inspection and measurement equipment, allowing them to conduct thorough quality control checks at every stage of the machining process. This meticulous attention to detail ensures that every part they produce meets the highest standards of quality and accuracy.As the demand for precision-machined small parts continues to grow across industries, {Company Name} is well-positioned to meet the evolving needs of their customers. Their ability to deliver complex, high-quality components with unmatched precision sets them apart in the competitive world of manufacturing. With a focus on innovation, quality, and customer satisfaction, they are a go-to partner for companies seeking reliable custom small parts machining solutions.In conclusion, {Company Name} is a powerhouse in the field of custom small parts machining. With their unwavering commitment to excellence, cutting-edge technology, and a team of dedicated professionals, they are revolutionizing the way precision-machined parts are produced. As industries continue to demand increasingly complex and high-quality components, {Company Name} stands ready to meet the challenge and exceed expectations.

The Ultimate Guide to CNC Machined Products: Everything You Need to Know

When it comes to manufacturing precision parts for various industries, {} has been a leader in providing high-quality CNC machined products. CNC (Computer Numerical Control) machining is a process that utilizes computerized controls to manipulate tools and machinery to produce complex and intricate parts with unmatched precision. With the latest technology and state-of-the-art equipment, {} has been able to consistently deliver top-notch CNC machined products to their clients across the globe.{} is a renowned company that specializes in providing a wide range of CNC machining services for industries such as aerospace, automotive, medical, and more. Their commitment to quality, precision, and innovation has set them apart from their competitors, making them a trusted and reliable partner for companies in need of high-quality machined products.The CNC machined products offered by {} are manufactured using a variety of materials, including aluminum, steel, titanium, and plastics. Whether it's a simple part or a complex component, their team of skilled engineers and technicians have the expertise and knowledge to produce parts that meet the exact specifications and requirements of their clients. By utilizing advanced CAD/CAM software and modern machining centers, {} can produce parts with tight tolerances, intricate geometries, and superior surface finishes.One of the key advantages of CNC machining is its ability to produce parts with a high degree of accuracy and consistency. With the use of computerized controls, {} can ensure that each part they manufacture meets the strictest quality standards, resulting in parts that are reliable and perform as intended. This level of precision is essential for industries such as aerospace and medical, where the performance and reliability of parts are critical.In addition to their commitment to quality, {} also places a strong emphasis on continuous improvement and innovation. They invest in the latest CNC machining technology and equipment to stay ahead of the curve and provide their clients with cutting-edge solutions. By staying abreast of the latest advancements in CNC machining, {} is able to offer their clients improved efficiency, reduced lead times, and cost-effective solutions.Furthermore, {} prides themselves on their ability to work closely with their clients to understand their unique needs and requirements. They offer tailored solutions that are customized to meet the specific demands of each project. Whether it's a prototype, a low-volume production run, or a high-volume manufacturing project, {} has the capabilities to deliver the right CNC machined products on time and within budget.Another aspect that sets {} apart from their competitors is their unwavering dedication to customer satisfaction. They have built a reputation for providing exceptional customer service, transparent communication, and a proactive approach to problem-solving. Clients who partner with {} can expect a seamless and hassle-free experience from the initial consultation to the delivery of the final product.With a strong track record of delivering top-quality CNC machined products, {} has earned the trust and confidence of their clients, both domestically and internationally. Their commitment to excellence, innovation, and customer satisfaction has positioned them as a leader in the CNC machining industry.In conclusion, {} is a reputable company that excels in providing high-quality, precision CNC machined products for a wide range of industries. With their state-of-the-art technology, skilled workforce, and customer-centric approach, {} is well-equipped to meet the evolving needs of the manufacturing sector and continue to be a trusted partner for businesses seeking top-notch CNC machined products.

3 Axis CNC Machining Suppliers: A Guide to Finding the Best Services

3 Axis CNC Machining Suppliers on the Rise: Meeting the Growing Demand for Precision PartsIn today's fast-paced manufacturing industry, the demand for high-quality precision parts is on the rise. With the increasing complexity of products and the need for tight tolerances, manufacturers are turning to 3 axis CNC machining suppliers to meet their production needs. These suppliers are equipped with advanced technology and expertise to produce complex parts with close tolerances, making them an essential part of the modern manufacturing process.One such company at the forefront of this industry is {}, a leading 3 axis CNC machining supplier. Specializing in providing precision machining services for a wide range of industries, {} has established a strong reputation for delivering high-quality parts with unmatched precision and accuracy. From aerospace and automotive to medical and electronics, the company has successfully catered to the diverse needs of its customers, earning their trust and loyalty.With a state-of-the-art facility equipped with the latest CNC machining technology, {} has the capability to handle even the most complex and challenging projects. The company's team of highly skilled machinists and engineers work closely with customers to understand their specific requirements and provide customized solutions that meet or exceed their expectations. This commitment to quality and customer satisfaction has set {} apart from its competitors and positioned it as a leading player in the 3 axis CNC machining industry.As the demand for precision parts continues to grow, {} has expanded its capabilities to offer a wide range of machining services, including milling, turning, drilling, and more. The company's investment in advanced CNC machining equipment has enabled it to achieve high levels of accuracy and repeatability, ensuring that every part meets the strictest quality standards. Additionally, {} is committed to staying at the forefront of technological advancements in the industry, regularly updating its equipment and processes to maintain its competitive edge.In addition to its technological capabilities, {} places a strong emphasis on quality control and inspection throughout the production process. The company's dedicated quality assurance team conducts rigorous testing and inspection procedures to verify the accuracy and precision of every part, ensuring that only the highest quality products are delivered to customers. This attention to detail and commitment to quality has earned {} certifications and accolades for its outstanding performance in the manufacturing industry.With a customer-centric approach, {} strives to build long-term partnerships with its clients, offering rapid prototyping, flexible production runs, and on-time delivery to meet their specific needs. By understanding the unique challenges and requirements of each customer, {} is able to provide tailored solutions that optimize production processes and minimize costs. This level of personalized service has helped {} build a loyal customer base and establish itself as a trusted partner in the manufacturing supply chain.As the manufacturing industry continues to evolve, the role of 3 axis CNC machining suppliers like {} will become increasingly critical. With their advanced technology, expertise, and commitment to quality, these suppliers are well-positioned to meet the growing demand for precision parts across a wide range of industries. As a leading player in this space, {} is poised to continue its success and contribute to the advancement of manufacturing capabilities in the years to come.In conclusion, 3 axis CNC machining suppliers play a vital role in meeting the growing demand for precision parts in today's manufacturing industry. With their advanced technology, expertise, and commitment to quality, suppliers like {} are well-equipped to cater to the diverse needs of their customers and drive the industry forward. As the demand for high-quality precision parts continues to rise, the capabilities and contributions of 3 axis CNC machining suppliers will only become more significant.